KuUmkhakha Wokupakisha, ukukhiqizwa kanye nokucutshungulwa kwamabhokisi ahlanganisiwe kubeka izimfuno eziphakeme ekuvinjelweni kokugqoka, ubunzima kanye nobukhali bamathuluzi wokusika. Kuyo yonke le minyaka, i-tungsten Carbide isiphenduke izinto ezikhethiweImimese Ehlanganisiwe Ehlanganisiwengenxa yezakhiwo zayo ezinhle kakhulu zomzimba nezamakhemikhali. Kulesi sihloko, sibheka ukuthi yini eyenza i-tungsten carbide ivelele esixukwini njengesinqumo esihle kakhulu semimese esicwebezelayo.

I-Tungsten Carbide, eyaziwa nangokuthi iTungsten Carbide, iyinhlangano ye-alloy eyenziwe ngenqubo ye-powder metlurgical. Siqukethe i-tungsten carbide kanye nama-cobalt kanye nezinye izinsimbi zensimbi, futhi inochungechunge lwezinto ezinhle kakhulu ezifana nobulukhuni obuphezulu, ukumelana okuphezulu, amandla aphezulu nokuphikiswa kokugqwala. Lezi zakhiwo zenza ukunciphisa ama-tungsten carbide amabala ahle kakhulu ekubhekaneni namabhokisi ahlanganisiwe, ubulukhuni obuphezulu, impahla yamandla aphezulu.

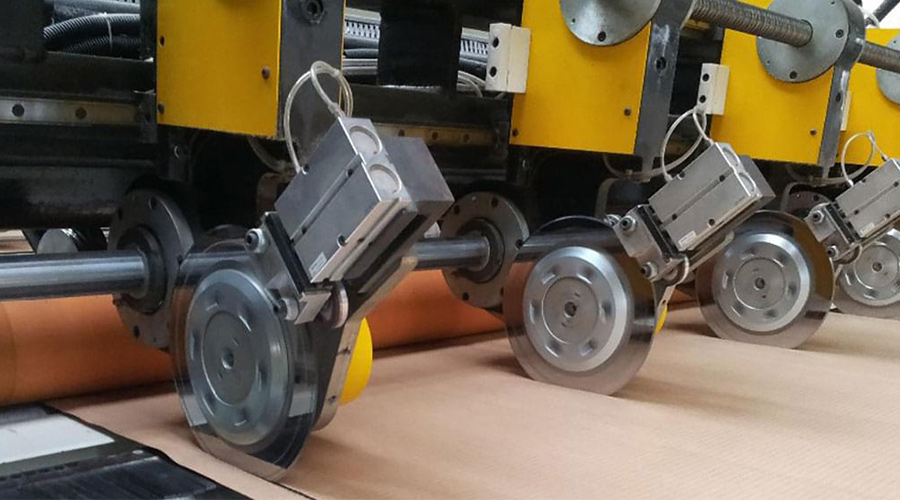

Inqubo yokusika yamabhokisi ahlanganisiwe idinga ama-blade ngokumelana nokugqoka okuphezulu kakhulu. Amathuluzi e-Carbide weTungsten Carbide anokuvimbela okungcono kakhulu kunezinto zokwenziwa zendabuko ezifana nensimbi enesivinini esiphakeme nensimbi engenasici. Lokhu kusho ukuthi ama-tungsten Carbide Blades anempilo yenkonzo ende, okuholela ngesikhathi sokuphumula kancane futhi akhiqize umkhiqizo. Embonini yokufaka, lokhu kusho izindleko zokulungiswa okuphansi kanye nokudlula okuphezulu.

Ubulukhuni obuphakeme be-tungsten Carbide buyisizathu esibalulekile esenza kube yinto efanelekile yokusika ibhokisi elihlanganisiwe. Ubulukhuni buyisilinganiso sekhono lokumelana nokumelana nokubhalwa phansi. Ngesikhathi sokusika amabhokisi ahlanganisiwe, i-blade idinga ukubekezelela ingcindezi ephezulu yokuqina nokuxabana. Ubulukhuni bukaTungsten Carbide buphakeme kakhulu kunalokho kwezinye izinto zokusika zendabuko, okukuvumela ukuthi kugcinwe ubukhali bomphetho isikhathi eside, buqinisekiswa.

Ngaphezu kokugqoka ukumelana nobulukhuni, i-tungsten Carbide nayo inokuvuka okuhle okushisayo. Ngesikhathi senqubo yokusika, i-blade ikhiqiza ukushisa, futhi uma ukushisa kungabikwa ngesikhathi, kuzoholela ekuguqukeni kwe-blade kanye nokuncipha komngcele. I-Thermal Cartivity ye-Tungsten Carbide isiza ukunciphisa umphumela we-thermal ngesikhathi senqubo yokusika, ukugcina ukuqina kwe-blade nokusika ukunemba.

Ama-tungsten Carbide Blades ayakwazi futhi ukufeza imiphumela yokunciphisa elisebenzayo futhi eqondile yenqubo yebhokisi lokusika ibhokisi elihlanganisiwe. Lokhu kubalulekile ukuvikela okuqukethwe ekuhlukaniseni phakathi kwezendlalelo noma ukuhlukunyezwa emaphethelweni. Ikakhulu kubuchwepheshe bokusika kwe-ultrasonic, ukusebenza okuhle kakhulu kwama-tungsten Carbide Blades kunikezwa ukudlala okugcwele, ukuthuthukisa ukusebenza kahle kanye nokucubungula ikhwalithi yokusika.

Ngokufingqa, i-tungsten Carbide iyinto engcono kakhulu yeAma-blades wokusika amaphepha ahlanganisiweNgenxa yobulukhuni bayo obuphezulu, ukumelana okuphezulu okuphezulu, amandla aphezulu nokusebenza okuhle okushisayo. Akugcini nje ngokuthuthukisa umkhiqizo futhi kunciphise izindleko zokulungiswa, kepha futhi kuqinisekisa ukusika ikhwalithi nokunemba. Ngokuthuthuka okuqhubekayo kwe-blade design kanye nesayensi yezinto ezibonakalayo, ukusetshenziswa kweTungsten Carbide Blades embonini yokupakisha kuzoba nekusasa elibanzi, ukuhlinzeka ngezisombululo ezingcono zokucutshungulwa okusebenzayo nokunembile.

Kamuva, sizoqhubeka nokuvuselela imininingwane, futhi ungathola imininingwane eminingi ngebhulogi lethu lewebhusayithi (i-passiontool.com).

Vele, ungabhekisisa nemidiya yethu esemthethweni yezenhlalo: