Esihlokweni sokugcina sifunde ukuthi yiliphi ubuchwepheshe be-CNC kanye nezinhlobo ezahlukene nemisebenzi ye-CNC Knife blades. Namuhla, siyaqhubeka nokuchaza ukusetshenziswa kwe-CNC Knife Blades emikhakhelweni ehlukahlukene, izici okufanele zibhekwe lapho ukhetha ama-CNC Knife blades nezinzuzo zeI-CNC Knife Blades.

Izicelo ze-CNC Knife Blades ezimbonini ezahlukahlukene

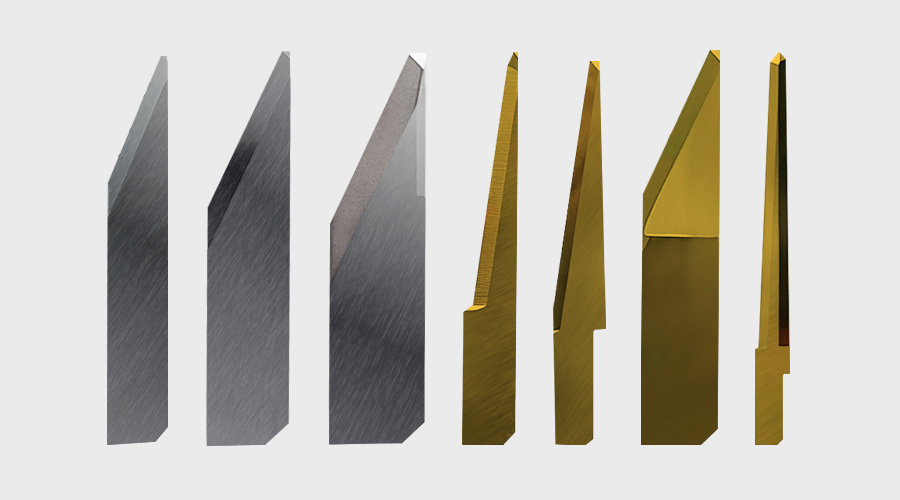

Ukuguquguquka okuhlukahlukene kanye nokunemba kwe-CNC Knife Blades kubenze babenze basebenzise amathuluzi asemqoka ezinhlotsheni eziningi zezimboni, lapho ukusika, ukubumba, nokuqoshwa kwezinqubo ezibalulekile. Embonini ye-WoodworKing, i-CNC Knife blades isetshenziselwa ukusika okunembile kwezinto zokhuni ukudala ifenisha yangokwezifiso, amakhaberi ekhabinet, nezinto zokuhlobisa. Amandla okuthola ukwakheka okuyinkimbinkimbi kanye nokuqedwa okubushelelezi kwenza ama-CNC Knife Blades athandwa phakathi kwabasebenza ngokhuni abafuna ubungcweti obusezingeni eliphezulu nokunemba.

Emkhakheni we-Signage and Graphics, ama-CNC Knife Blades adlala indima ebalulekile ekunciphiseni i-vinyl, ibhodi legwebu, nezinye izinto ezisetshenziselwa ukukhiqizwa kwezimpawu. Amandla okusika izinhlamvu eziqondile, ukwakheka kanye nama-logo anemiphetho ehlanzekile nezindawo ezibushelelezi zenza ama-CNC Knife ama-blade alungele ukudala izibonakaliso nokuboniswa kochwepheshe. Ijubane nokunemba kwemishini ye-CNC efakwe ama-Knife amabala anika amandla abenzi bezimpawu ukukhiqiza imikhiqizo esezingeni eliphakeme ngokushesha nangendlela efanele.

Ezimbonini zezimoto nezithutha, ama-CNC Knife blades asetshenziselwa ukusika ama-gaskets, izimpawu zezimpawu nezinto ezihlanganisiwe ngokunemba nokungaguquguquki. Amandla okuthola ukubekezelelana okuqinile kanye nobumba obuyinkimbinkimbi kubalulekile kule mikhakha, lapho izinto zokusebenza okuphezulu nemiklamo eyinkimbinkimbi ivamile. Ama-CNC Knife Blades ahlinzeka ngokunemba nokuthembela okudingekayo ukuze ahlangabezane nezidingo eziqinile zezicelo eziqinile zezicelo zezimoto nezama-aerospace, ukuqinisekisa ikhwalithi kanye nokwethembeka emikhiqizweni eqediwe.

Izici okufanele zicatshangelwe lapho ukhetha i-CNC Knife Blad

Lapho ukhetha i-CNC Knife blade yesicelo esithile, kufanele kubhekwe izinto eziningana ukuze kuqinisekiswe ukusebenza kahle nasekusebenzeni kahle. Enye yezinto ezibalulekile zokucatshangelwa ukuthi izinto ezibonakalayo ziyasikwa, njengoba izinto ezahlukene zidinga izinhlobo ezithile ze-blade kanye nokusika kwamapharamitha ukufezekisa ukusikeka okuhlanzekile nokunembile. Izinto ezinzima ezinjengezinsimbi zingadinga ama-carbide noma ama-blade ahlanganiswe ama-cail ukuze anqume okusebenzayo, ngenkathi izinto ezithambile ezinjengezinkuni zingasikwa kahle ngama-speed speeb (HSS) blades.

Enye into ebalulekile okufanele icatshangelwe isivinini sokusika kanye nesilinganiso sokuphakelayo, esinquma isilinganiso lapho ibala lihamba kulokhu okuqukethwe. Ukushintsha la mapharamitha ngokuya ngezakhiwo ezibonakalayo kanye nohlobo lwe-blade kubalulekile ukuze ufinyelele ekunciphiseni okubushelelezi nokunembile ngaphandle kokudala ukulimala kwezinto ezibonakalayo noma ngecala. Ngokwengeziwe, ukwakheka kwe-blade ne-blade kudlala indima ebalulekile ekusebenzeni kokusika, ukuthonya izinto ezifana nokuphuma kwe-chip, ukusika kanye nokuqedwa komhlaba.

Idizayini ephelele nokwakhiwa kwe-CNC Knife Blade nakho kuyaba nomthelela ekusebenzeni kwawo nokuphila isikhathi eside. Izici ezifana nokuqina kwe-blade, i-blade angle, kanye nekhwalithi yezinto ezibonakalayo kungathinta ukuqina kokuqina nokusika ukusebenza kahle. Ukukhetha i-blade ngenhlanganisela efanele yalezi zinto kubalulekile ukuze kukhuliswe umkhiqizo futhi uzuze imiphumela yokusika engaguquki. Ngokuhlola ngokucophelela lezi zinto futhi ukhethe i-CNC Knife blade evumelana nezidingo ezithile zephrojekthi, abakhiqizi bangathuthukisa izinqubo zabo zokusika futhi bathuthukise ikhwalithi ebanzi yokukhiqiza.

Izinzuzo zokusebenzisa i-CNC Knife Blades

Ukusetshenziswa kwe-CNC Knife Blades kunikeza izinzuzo eziningi ezinhlokweni zokukhiqiza, okwenza basebenzise amathuluzi asemqoka ekunciphiseni ukunciphisa kanye nemisebenzi yokubumba. Enye yezinzuzo ezisemqoka zeCNC Knife Blades yikhono labo lokuhambisa ukusikeka okungaguquki nokunembe, ukuqinisekisa ukufana kanye nekhwalithi emikhiqizweni eqediwe. Ukulawulwa okuqondile okuhlinzekwe yimishini ye-CNC kuvumela abakhiqizi ukuthi bafeze amacebo ayinkimbinkimbi kanye namajamo ayinkimbinkimbi kalula, athuthukise ama-aesthetics aphelele nokusebenza kwemikhiqizo yokugcina.

Enye inzuzo yokusebenzisa i-CNC Knife Blades ingukusebenza kahle nokukhiqiza okuletha emisebenzini yokukhiqiza. Ngokuzenzakalelayo imisebenzi yokusika kanye nokuqeda amaphutha ebhukwana, imishini ye-CNC efakwe nge-Knife Blades inganciphisa kakhulu isikhathi sokukhiqizwa nezindleko ngenkathi kukhuphuka okuphumayo. Ijubane eliphakeme lokusika kanye nokunemba kwe-CNC Knife Blades nika abakhiqizi ukuthi basebenzise izinqubo zabo futhi bahlangabezane nesikhathi sokugcina abakhiqizayo ngaphandle kokuyekethisa ngekhwalithi.

Ngaphezu kwalokho, ama-CNC Knife Blades anikela ngokuhlukahluka ekunciphiseni ukwahluka kwezinto zokwakha, kusuka kuma-softwoods namapulasitiki kuya ezinhlamvwini nama-composites. Lokhu kuguqulwa okuvumela abakhiqizi ukuthi baphathe amaphrojekthi ahlukahlukene kanye nezinto zokwakha ngethuluzi elilodwa, ukunciphisa isidingo sokusikwa okuningi kanye nokwenza lula ukugeleza komsebenzi wokukhiqiza. Noma ngabe usika amaphethini ayinkimbinkimbi ezintweni ze-acrylic noma zokunciphisa ngokunemba, ama-CNC Knife blades ahlinzeka ngokuguquguquka nokuzivumelanisa nezimo ezidingekayo ukubhekana nezinselelo ezahlukahlukene zokusika kahle.

Yilokho konke ngale ndatshana. Uma udinga lokhuI-CNC Knife BladesNoma ube nemibuzo ethile ngakho, ungaxhumana nathi ngqo.

Kamuva, sizoqhubeka nokuvuselela imininingwane, futhi ungathola imininingwane eminingi ngebhulogi lethu lewebhusayithi (i-passiontool.com).

Vele, ungabhekisisa nemidiya yethu esemthethweni yezenhlalo:

Isikhathi sePosi: Aug-28-2024